Manufacturer of Industrial Valves,ball valves,flters,china Valves Factory

Manufacturer of Industrial Valves,ball valves,flters,china Valves Factory

(This article and pictures are reprinted from the Internet for readers' reference only.)

Valve solutions for eliminating emissions and going green

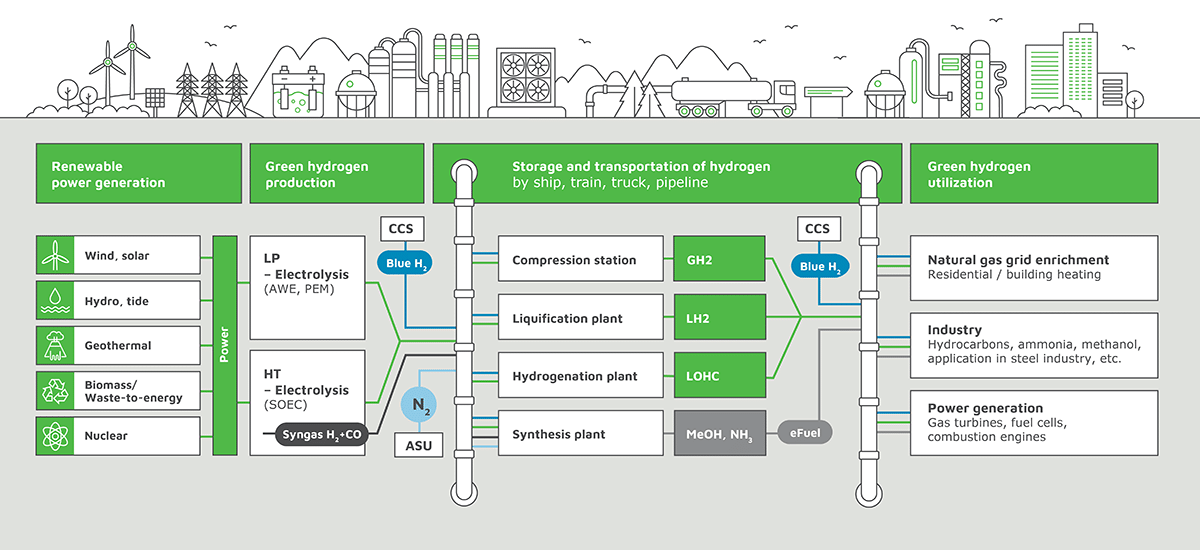

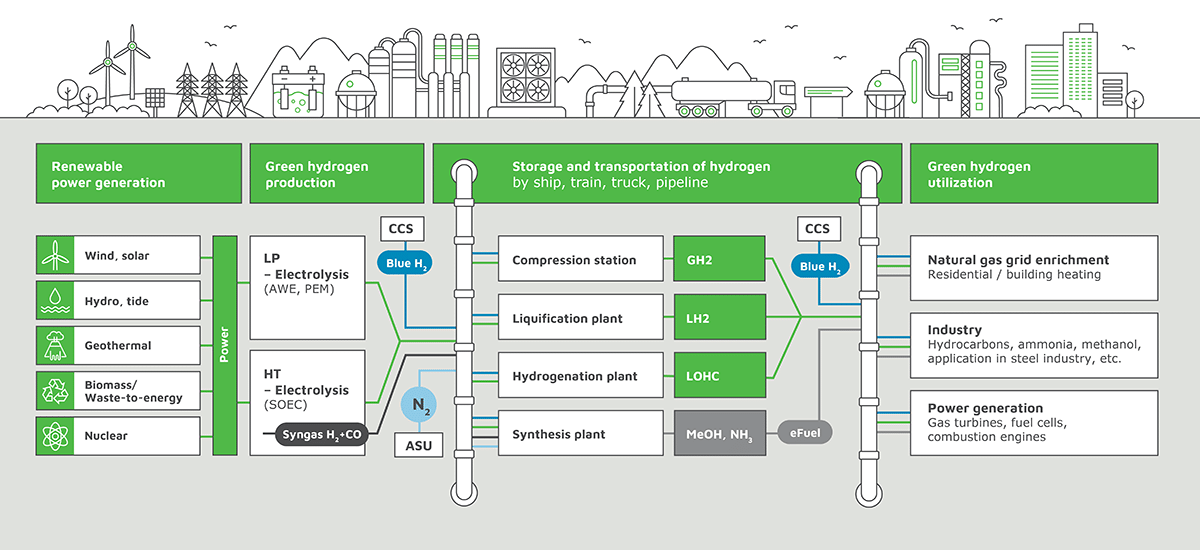

A carbon-neutral value chain

Neles power-to-x offering

Green hydrogen production

Green hydrogen refers to H2 produced from water utilizing surplus renewable energy by the process of electrolysis.

Our valves portfolio already fulfils the requirements of electrolysis applications as for the PEM, AWE or SOEC electrolyzers of both today and tomorrow.

Transportation of hydrogen

The transportation of hydrogen typically requires either compression or liquification. Longer distance transportation is covered by tankers carrying liquid hydrogen or the less energy-intensive liquid carriers (LHC).

Whether hydrogen is carried liquefied or by using ammonia (NH3) or the organic subset of liquid carrier (LOHC), xiongxiang valve is one of the few valve manufacturers that has the capacity and capabilities needed to deliver.

Green hydrogen utilization

Green hydrogen has many uses in the industrial gas sector. It is most often applied to fertilizer production with Ammonia synthesis or as feedstock for chemicals.

Our long-term experience in the refinery and chemical industries also help to make the usage of emission-free produced gases and liquids such as eAmmonia, eMethane, Methanol and eHydrocarbons more efficient.

Another important future usage is seen with the green fueling of fuel gas turbine. Our segment and ball valves help reach the higher pressure classes required due to the H2 enrichment of the fuel gas.

Carbon capture and storage (CCS)

Carbon capture as a means of eliminating harmful CO2 emissions into the atmosphere is a key factor in developing more sustainable industrial processes.

Each of these processes will benefit from xiongxiang valve's reliable, durable and high-quality valves.

Most CO2-removal, for instance in Steam Methane Reforming (SMR), are done by Pressure Swing Adsorbtion (PSA), see more information on page Valves for swing adsorption